We are Manufacturer, Supplier, Exporter of Co Generation Conveyors and our setup is situated in Sangli, Maharashtra, India.

Co generation, also known as Combined Heat and Power (CHP), is a process where electricity and useful heat are generated simultaneously from the same fuel source. In sugar factories, the bagasse (a residue after sugar production ) is used to manufacture electricity.

It's an efficient way to utilize energy resources because it captures and utilizes waste heat that would otherwise be wasted in conventional power generation processes.

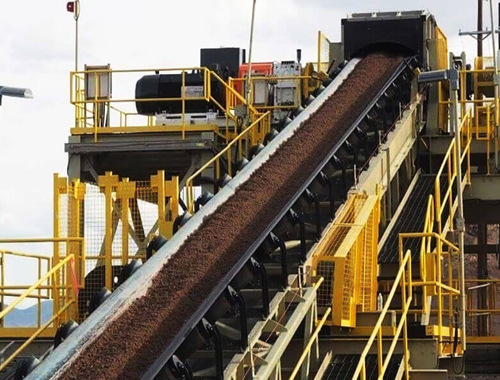

Conveyors play a role in co generation Systems primarily in the handling of fuel sources like biomass, coal, or waste materials, which are often used in these Systems.

Here's how conveyors might be involved :